Home » VORTEX® Engine Precleaners » Series 9000

Series 9000 Precleaner

Air filter life is directly related to the amount of debris ingested through an engine’s air intake. Installing a Sy‑Klone Precleaner as the first stage of an air intake system prevents the majority of heavier-than-air particles from entering the system. This results in longer air filter life, more efficient engine performance and decreased maintenance expenses.

- Series 9000 Savings Calculator: See how much you can save.

- Series 9000 Sizing Calculator: Find the correct model for the airflow of your engine.

Series 9000 Benefits:

- Extends air filter life, which increases uptime

- Handles all kinds of mixed debris, including mud, snow, rain, leaves, sawdust, chaff, and dust

- Lowers cost per operating hour by reducing parts, labor, and downtime costs

- Lowers air restriction, which increases useable horsepower and improves fuel efficiency

- Easy to install – we have adaptation kits and parts to fit almost any machine

- Claims against our limited warranty are practically nonexistent

- Rugged engineered polymer construction gives you the strength of steel (without the corrosion) at the cost of plastic; the opaque material prevents operator being distracted by visible moving parts

How it Works:

- Air enters the underside of the dome through screened louvers, which prevents clogging by blocking any particles larger than the ejection slot from entering the unit.

- Curved particle accelerator blades slam air and dirt up against the sidewall

- Strakes along the interior surface move heavier-than-air debris towards the ejection slot

- Clean air continues to swirl down into the engine air inlet pipe

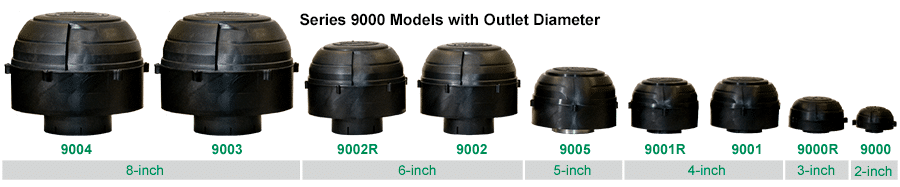

Models, Airflow, Dimensions & Hood Clearances

IMPORTANT NOTES:

It is essential that you select the correct model based on CFM (m3/min) airflow requirements, not air inlet size (A). If you do not know the required airflow, see our online Series 9000 Sizing Calculator. If you cannot determine the correct precleaner from this matrix or the calculator, please contact our technical support department for assistance

You must allow adequate clearance between the hood and the base of the precleaner for it to function properly. There are extension pipes and other adaptation parts available to increase clearance when necessary. Contact your Dealer or Sy-Klone for details.

Airflows above 1400 CFM (39.64 m3/m) can be handled with multiple unit installations. Please contact Sy-Klone for assistance. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Design:

Mounting & Equipment Types:

Mounts on all vertical and horizontal air cleaner housings, on all machines, replacing those with rain caps, tube body systems or internal precleaners

Construction:

Engineered polymer is rugged and gives the strength of metal with the weight of plastic. Patented sealed bearing cavity protects bearings from debris and moisture, preventing corrosion. Grease concentration of 20% instead of the typically used 10-15% concentration allows the Series 9000 to operate in extreme cold weather, down to -40½°F.

Precleaner Maintenance:

Self-cleaning and routine maintenance-free, as no debris is trapped within the precleaner.

Recommended Uses:

Off-road conditions, construction, mining, forestry, landfill & waste, farming & agriculture, military, highway, and more.

Debris Types:

Expels all types of mixed debris, including mud, snow, rain, leaves, sawdust, chaff, and dust. The Series 9000 is the only precleaner on the market today that can handle wet debris such as snow and sleet as well as it handles dry debris!

Screens:

The standard included prescreen is adequate for most situations, and prevents clogs by keeping out debris larger than the ejection slot. In extreme winter weather, the removable prescreen can be dropped down the air inlet pipe to avoid blinding over with snow and ice.

The perforated metal heavy-debris screen is recommended for extreme-debris situations such as landfill and forestry.

The agricultural screen is perfect for finer debris such as chaff.

Downloads

Resources Available

- Technical Specifications

- Installation Guides

- Operation Manuals